MANUFACTURING SERVICES

At SCS Interiors, we’re known for our high-quality carpet and upholstery kits for small aircraft. But we also support custom manufacturing projects across a range of industries. Whether you’re developing a new product line or need custom-cut materials for a specialized application, our team is equipped to bring your vision to life.

Design & Prototyping

Transforming concepts into full-scale prototypes by blending creative vision with practical engineering. Our process emphasizes aesthetics, ensuring each prototype reflects a polished, professional appearance; durability, using materials and construction methods that withstand real-world conditions; and cost-effectiveness, optimizing resources without compromising quality. From initial sketches to working models, we bridge the gap between ideas and implementation—delivering prototypes that are not only visually compelling but also functional and ready for real-world testing or presentation.

Foam Fabrication

Custom foam solutions crafted to meet your exact needs—available in a wide range of shapes, sizes, and densities. Whether you're looking for protective packaging, cushioning inserts, insulation, or structural components, our foam products are precision-engineered and tailored to your specifications. We work closely with you to understand the specific requirements of your application, including performance standards, environmental factors, and aesthetic preferences. With advanced cutting and fabrication capabilities, we deliver high-quality, consistent results—ensuring every foam solution offers the perfect fit, optimal functionality, and reliable performance.

High-Speed Precision Cutting

Utilizing advanced equipment for precise and efficient material cutting, we ensure every component meets exact specifications with minimal waste and maximum consistency. Our state-of-the-art machinery, including CNC cutters and laser systems, allows us to handle a wide range of materials—from foam and plastics to metals and composites—with speed and accuracy. This technology-driven approach not only improves turnaround times but also enhances the overall quality of the finished product. Whether producing one-off prototypes or high-volume production runs, our cutting capabilities support tight tolerances, complex designs, and scalable results for virtually any industry or application.

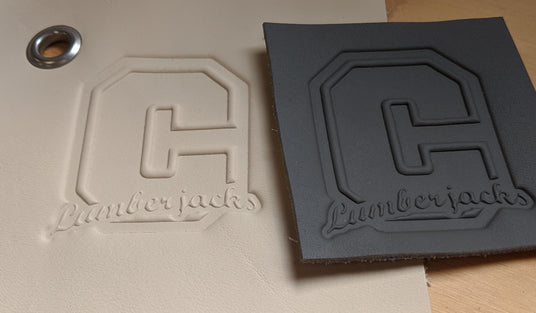

Embossing and Debossing

Adding personalized touches to leather and other materials by incorporating your logos, artwork, or custom designs with precision and care. Whether you're looking to enhance a product’s visual appeal, strengthen your brand identity, or create a unique customer experience, our customization services deliver professional, lasting results. We utilize advanced techniques such as embossing, debossing, laser engraving, and printing to ensure your design is accurately reproduced on a variety of surfaces—including leather, vinyl, fabric, and synthetic materials. From corporate branding to one-of-a-kind gifts, we help you turn ordinary items into distinctive, high-impact pieces that reflect your style and purpose.